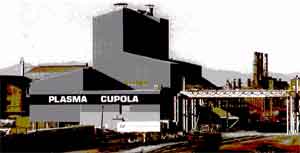

Geneva Steel Plasma Cupola

Commissioned in 1997

- Supplemental Hot Metal Production

- Marc - 11H Torch

– 9 active, 2 spares - Nominal Power :

– Total System : 18 MW

– Individual Torch : 800-2400 KW - Process Gas : Air

- Electrode Life :

– Anode : 1500 Hours

– Cathode : 750 Hours

Plasma fired cupola at Geneva Steel in Provo, Utah is largest in the world and is designed to produce up to 1 million tons per year of hot metal as supplemental iron..

Charge material is scrap, pit scrap, direct reduced iron DRI, reverts, and oxidic material.

The plasma melter consist of 156" diameter cupola with water walls and dry bottom with below charge top gas take off.

The cupola has nine tuyeres with each having a 2.4 MW Westinghouse Marc-11H plasma torch.